From Humble Beginnings to the Big Leagues: The Story of DDR Motorsports

Humble Beginnings Breed Passion

The story of DDR Motorsports begins not on the asphalt tracks of today but in the gritty world of street stocks. This is where Doug Robbie, the team’s patriarch, honed his racing skills and ignited a lifelong passion for motorsports. By the early 1990s, Doug had transitioned to the prestigious Winston Modified Tour, turning wrenches for some of the top drivers in the series until the late 2000s. These formative years laid the groundwork for the competitive spirit that continues to drive DDR Motorsports forward.

A Family Affair Takes the Wheel

In 2004, a new chapter unfolded. Fueled by a desire to support the racing dreams of Doug’s children, Derek and Danielle, DDR Motorsports was born. The team’s initial focus shifted to Quarter Midgets, scaled-down sprint cars perfect for youngsters. Competing across multiple classes at various tracks throughout the Northeast, Derek and Danielle showcased their talent, racking up numerous victories and milestones. By 2009, it was time for the next challenge.

Embracing the Dirt: Building Versatility

Seeking to broaden their horizons, DDR Motorsports ventured into the world of dirt racing at Whip City Speedway in Westfield, MA. This formative period proved invaluable, helping Derek develop the versatility and resilience required to succeed in competitive racing. After a year and a half of mastering the dirt tracks, it was time to set their sights on a new challenge.

Pro Four Modified Dominance: A Foundation for Success

The team’s next move was to the Pro Four Modifieds of New England, marking the beginning of a highly successful chapter. These exciting 4-cylinder open-wheel racers provided the perfect platform to hone Derek’s skills on tracks that would eventually lead him to the bigger and faster 8-cylinder classes. During this period, Derek earned Rookie of the Year honors twice (2011 – Pro4 Lites, 2014 – Full Pro4). Additionally, DDR Motorsports captured the Pro4 Lite championship in 2013 and narrowly missed the Full Pro4 title in 2015, falling just short in a tiebreaker. The knowledge and experience gained with these cars laid the foundation for the team’s transition to the high-powered Tour-type cars.

Taking on the Tour-Type Modified Challenge

In 2017, DDR Motorsports made a bold move, entering the prestigious Modified Racing Series and going head-to-head with renowned drivers like Teddy Christopher and Anthony Nocella. This leap into the world of Tour-type Modifieds showcased the team’s ambition and skill. Drawing upon Doug’s experience from the Winston Modified Tour, DDR Motorsports consistently placed in the top finishes during their initial seasons. As their experience grew, they ventured into open competition shows, further testing their mettle in the Monaco Tri-Track Series.

Adapting and Overcoming: Embracing New Challenges

The past two years have presented their share of challenges, with engine failures and unavoidable mishaps disrupting the 2023 and 2024 seasons. However, the team remained resilient. Partnering with Mike Horn in an ultra-fast and nimble NEMA Midget allowed Derek to sharpen his skills and ensure continuous growth even amidst setbacks. Through it all, DDR Motorsports never lost sight of their modified roots, ensuring every decision and plan ultimately strengthened their core program.

The Power of Partnership: Fueling the Drive for Excellence

The success of DDR Motorsports is deeply rooted in the unwavering support of their sponsors. From the durability ensured by New Hampshire Oil Undercoating to the skilled workforce connections provided by Skilled Trades Partners, each collaboration plays a vital role. Road Active Suspension enhances stability for the team’s hauler, while Strasburg Performance and Ashaway Performance Engines provide both reliable power and handling – crucial elements for competitive racing. Uniquely, DDR Motorsports effectively promotes these partnerships, showcasing their services across various channels. This collaborative effort fuels the team’s drive for excellence on every level.

The Road Ahead: Setting a Course for the Whelen Modified Tour

DDR Motorsports now sets its sights on the ultimate level of competition: the Whelen Modified Tour – NASCAR’s oldest division and the pinnacle of Tour-type modified racing. As the team has matured and honed its craft, they look to reach for the stars. Though not for the faint of heart, the team is not shy in chasing this goal. They believe a detailed plan, hard work, the correct resources, and, of course, a little luck can achieve the goal. The team also understands reaching this milestone will require increased funding and strategic partnerships. With unwavering determination and a strong brand, the team seeks to collaborate with sponsors who share their vision for success.

A Legacy Built on Passion: The Journey Continues

The story of DDR Motorsports is one of resilience, innovation, and an unwavering passion for racing. It is a testament to a family dedicated to achieving greatness on the track.

Ready to Join the Ride?

Interested in partnering with DDR Motorsports and being part of their journey to the top? Contact the team at info@ddr-motorsports.com to learn how your company can benefit from this exciting collaboration.

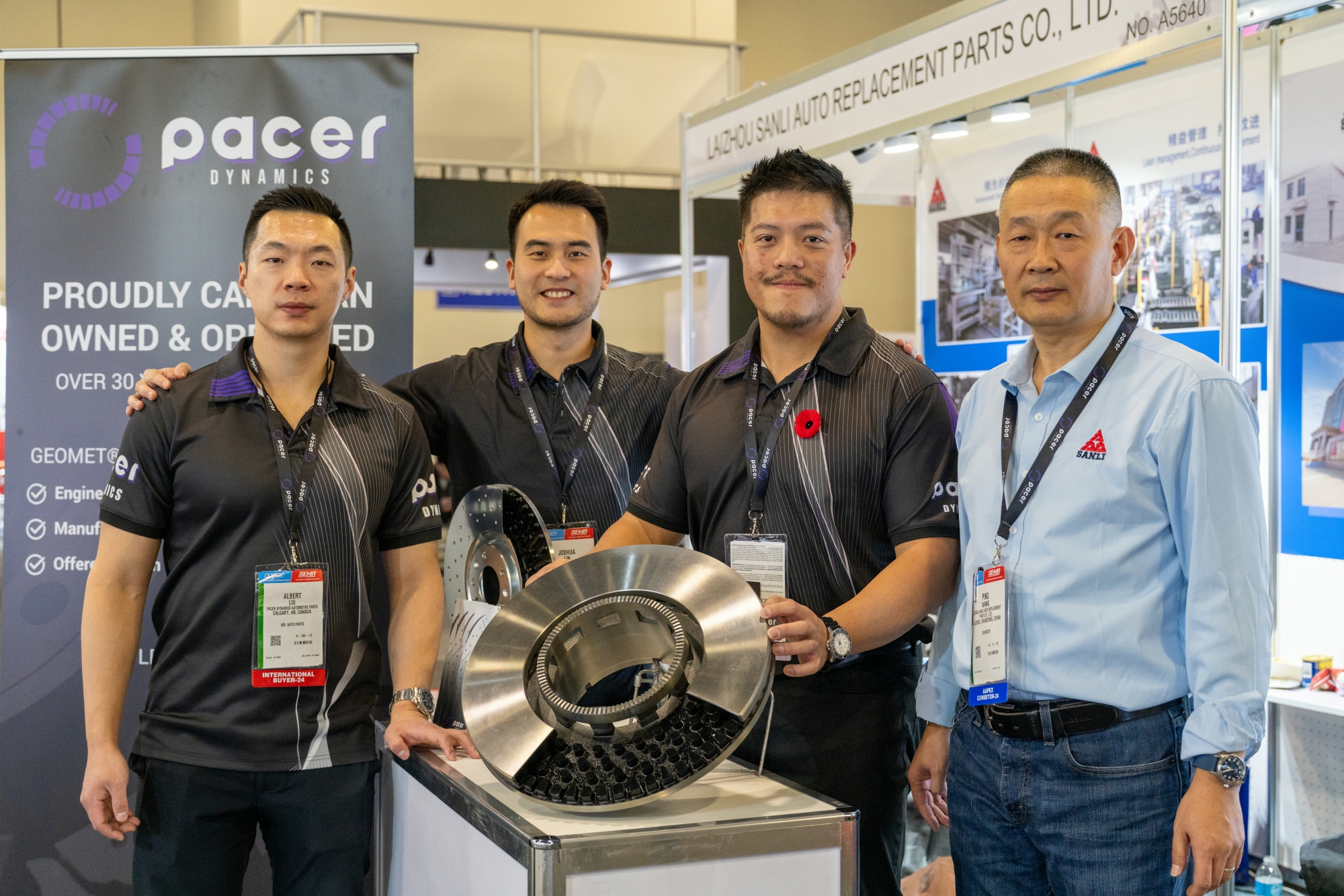

Pacer Dynamics Automotive: Elevating Brake Rotor Standards Across North America

The automotive industry is evolving rapidly, and Pacer Dynamics Automotive is rising to the challenge with precision-engineered brake solutions tailored to a wide range of vehicle segments, prioritizing passenger vehicles, medium-duty trucks, heavy-duty fleets, and performance applications. Guided by core values—delivering customer experience excellence, ensuring consistent quality, and promoting sustainability by minimizing waste throughout the value chain and the product lifecycle—Pacer Dynamics combines time-tested practices with modern technology to meet the demands of a dynamic market.

At the heart of Pacer Dynamics’ offerings is its high-carbon brake rotor line, designed to meet rigorous European standards (ECE R90) for durability and performance in the aftermarket. Pacer Dynamics’ rotors are produced in a generationally owned 2.1 million sq. ft. factory with an annual production capacity of over 13 million rotors. With contributions from both its Canadian and international teams, consistent quality and reliability are ensured across all applications.

“Our products are carefully designed to meet the unique demands of each application,” says Eddie Tso, Chief Executive Officer (CEO) of Pacer Dynamics. “With every step of the production process handled in-house—including smelting, mold creation, and design—we maintain precise control over material quality and product consistency. Additionally, rigorous quality control and assurance processes at every stage ensure that our products meet the highest standards of performance and reliability.”

A Vision Shaped by Strategic Partnerships and Industry Guidance

As Pacer Dynamics continues to expand in North America, it has established key partnerships and embraced valuable guidance from respected industry leaders. Its strategic partnership with Specialty Sales & Marketing (SS&M) ensures its product line is effectively represented in Canada, providing localized expertise and market insights that benefit distributors and mechanics alike.

Additionally, the rapid evolution of data catalogs and advanced digital tools, has become a critical success factor in the automotive industry. Continuously staying ahead of the curve has yielded strong competitive advantages and returns on investment. By leveraging structured and accessible data, Pacer Dynamics is able to provide its partners with streamlined, accurate information that enhances decision-making and operational efficiency. Partnering with RevolutionParts have been pivotal in Pacer Dynamics’ digital transformation, enabling the company to deliver an exceptional customer experience.

Pacer Dynamics has also benefited from the guidance of automotive industry veteran Joe Mercanti, whose expertise has helped shape the company’s strategic initiatives and approach to collaboration within the industry.

“The advice and perspectives we have received have been instrumental in navigating the complexities of a competitive market,” says Joshua Lin, Chief Revenue Officer (CRO) of Pacer Dynamics. “With strong partnerships and trusted guidance, we are well-positioned to serve the diverse needs of the North American automotive aftermarket.”

A Vision Shaped by Strategic Partnerships and Industry Guidance

Pacer Dynamics is driven by a leadership team that embodies its values and vision:

- Eddie Tso, Chief Executive Officer (CEO): Eddie sets the strategic direction for the company while collaborating closely with Joshua Lin to drive market growth and position Pacer Dynamics as a leading brand.

- Joshua Lin, Chief Revenue Officer (CRO): Joshua leads efforts to identify and capitalize on growth opportunities across North America, driving market expansion and fostering strong partnerships throughout key markets.

- Albert Liu, President and Chief Operating Officer (COO): Albert oversees daily operations, ensuring manufacturing processes meet the company’s high standards for quality and efficiency. His expertise enables Pacer Dynamics in delivering consistent results across its product lines.

Together, this team is focused on scaling Pacer Dynamics’ presence across the U.S. and Canada, prioritizing precision engineering, sustainable practices, and collaborative partnerships.

As Pacer Dynamics continues to expand, it remains committed to delivering reliable solutions tailored to the needs of its North American partners, ensuring its products perform as expected—every time.

Driving Innovation in Auto Parts Manufacturing: What’s Next?

The Rise of Digital Manufacturing

One of the most significant trends in auto parts manufacturing is the rise of digital manufacturing. This includes technologies such as 3D printing, robotic automation, and artificial intelligence that are revolutionizing the way parts are designed, produced, and tested. Companies that embrace digital manufacturing are able to streamline their processes, reduce costs, and improve the quality of their products. This trend is only expected to continue growing in the coming years as more companies see the benefits of these technologies.

Sustainability and Green Initiatives

Another important aspect of innovation in auto parts manufacturing is sustainability and green initiatives. With consumers becoming increasingly environmentally conscious, companies are under pressure to reduce their carbon footprint and produce more eco-friendly products. This has led to the development of new materials, production methods, and technologies that are helping to make the industry more sustainable. By focusing on sustainability, companies can not only attract environmentally conscious customers but also reduce their impact on the planet.

Customer-Centric Design

Innovative companies are also starting to shift towards a more customer-centric approach to design. Instead of just focusing on functionality and cost, companies are now considering the overall customer experience when developing new products. This means taking into account factors such as aesthetics, ease of use, and brand perception to create products that truly resonate with consumers. By humanizing their approach to design, companies can create products that not only meet the needs of their customers but also build strong emotional connections with them.

Collaboration and Partnerships

Collaboration and partnerships are also key drivers of innovation in auto parts manufacturing. By working together with other companies, research institutions, and industry experts, companies can leverage their collective knowledge and resources to drive innovation forward. This can lead to the development of new technologies, processes, and products that would not have been possible otherwise. By fostering a culture of collaboration, companies can stay at the forefront of innovation and ensure they are constantly pushing the boundaries of what is possible in the industry.

Investing in Research and Development

Lastly, investing in research and development is essential for driving innovation in auto parts manufacturing. Companies that allocate resources to R&D are able to stay ahead of trends, anticipate market changes, and develop cutting-edge products that set them apart from the competition. By continuously investing in innovation, companies can ensure they are well-positioned for success both now and in the future. This commitment to R&D is what will drive the industry forward and lead to the next wave of groundbreaking advancements.

Conclusion: Embracing Innovation and Human-Centered Design

The future of innovation in auto parts manufacturing looks bright. By embracing digital manufacturing, sustainability, customer-centric design, collaboration, and investing in R&D, companies can stay ahead of the curve and continue to drive the industry forward. However, it’s important for companies to not only focus on technological advancements but also on humanizing their approach to innovation. By connecting with customers on a deeper level and creating products that resonate with their needs and values, companies can build stronger relationships and set themselves apart in a crowded market. So, what’s next for innovation in auto parts manufacturing? Only time will tell, but one thing is for sure – companies that prioritize innovation and human-centered design will be the ones leading the way.

Navigating Supply Chain Disruptions: How Manufacturers Can Stay Ahead

The Risks

The first step in navigating supply chain disruptions is to understand the risks involved. Manufacturers must be aware of the potential disruptions that could impact their supply chain, whether it be a hurricane in a key shipping region or a labor strike at a crucial supplier. By identifying these risks early on, manufacturers can develop contingency plans to mitigate their impact.

Building Strong Relationships

One of the best ways for manufacturers to stay ahead in navigating supply chain disruptions is to build strong relationships with their suppliers and partners. By fostering open communication and collaboration, manufacturers can better respond to disruptions and work together to find solutions. When disruptions occur, having strong relationships in place can make all the difference in quickly resolving issues and minimizing the impact on operations.

Diversifying Suppliers

Another key strategy for manufacturers to stay ahead in navigating supply chain disruptions is to diversify their supplier base. Relying on a single supplier for a critical component or material can leave manufacturers vulnerable to disruptions if that supplier encounters issues. By diversifying suppliers and developing relationships with multiple sources, manufacturers can reduce their risk exposure and ensure a more stable supply chain.

Investing in Technology

In today’s digital age, technology plays a crucial role in helping manufacturers navigate supply chain disruptions. Investing in supply chain management software and tools can provide manufacturers with real-time visibility into their operations, allowing them to quickly identify disruptions and take action. By leveraging technology, manufacturers can proactively manage their supply chain and stay ahead of potential disruptions.

Developing Contingency Plans

One of the most important steps manufacturers can take to stay ahead in navigating supply chain disruptions is to develop comprehensive contingency plans. These plans should outline potential disruptions, their impact on operations, and steps to take in response. By having contingency plans in place, manufacturers can quickly react to disruptions and minimize their impact on production and customer satisfaction.

Staying Agile and Flexible

In the face of supply chain disruptions, it is crucial for manufacturers to stay agile and flexible in their operations. Being able to quickly adapt to changing circumstances and pivot when necessary can help manufacturers navigate disruptions more effectively. By staying agile and flexible, manufacturers can maintain a competitive edge and continue to meet customer demand, even in the face of disruptions.

Navigating supply chain disruptions is a critical challenge for manufacturers in today’s global economy. By understanding the risks, building strong relationships, diversifying suppliers, investing in technology, developing contingency plans, and staying agile and flexible, manufacturers can stay ahead and successfully navigate disruptions when they arise. By humanizing their approach to supply chain management and putting these strategies into practice, manufacturers can ensure the resilience and success of their operations in the face of disruption.

Sustainable Manufacturing in the Automotive Parts Industry: A Necessary Evolution

The Environmental Impact of Traditional Manufacturing Processes

Traditional manufacturing processes in the automotive industry rely heavily on fossil fuels and generate a significant amount of greenhouse gas emissions. The production of car parts often involves the use of toxic chemicals, heavy metals, and other harmful substances that can pollute the air, water, and soil. Additionally, the transportation of raw materials and finished products contributes to carbon emissions and exacerbates the environmental impact of the industry.

The Benefits of Sustainable Manufacturing

Sustainable manufacturing offers a more environmentally friendly alternative to traditional production methods. By using renewable energy sources, recycling materials, and reducing waste, manufacturers can significantly decrease their carbon footprint and minimize their impact on the environment. In addition to reducing greenhouse gas emissions, sustainable manufacturing can also lead to cost savings, improved resource efficiency, and enhanced brand reputation.

Implementing Sustainable Practices in the Automotive Parts Industry

To promote sustainability in the automotive parts industry, manufacturers can implement a variety of green practices and technologies. This may include investing in energy-efficient equipment, adopting green supply chain management techniques, and collaborating with suppliers who prioritize environmental stewardship. By integrating sustainability into every aspect of their operations, companies can create a more resilient and sustainable supply chain.

The Role of Innovation and Technology

Innovation and technological advancements play a crucial role in driving sustainable manufacturing in the automotive parts industry. New technologies such as 3D printing, advanced robotics, and intelligent manufacturing systems can help companies reduce waste, improve efficiency, and lower their environmental impact. By harnessing the power of innovation, manufacturers can develop innovative solutions that address the complex challenges of sustainability and create a more sustainable future for the industry.

The Importance of Collaboration and Partnerships

Collaboration and partnerships are essential for driving sustainable manufacturing practices in the automotive parts industry. By working together with industry stakeholders, government agencies, non-profit organizations, and research institutions, manufacturers can exchange knowledge, share best practices, and identify new opportunities for sustainable innovation. Through collaboration, companies can accelerate the adoption of sustainable manufacturing practices and create a more sustainable industry as a whole.

Advancing Towards a Sustainable Future

As the automotive industry continues to evolve, sustainable manufacturing practices will become increasingly important for companies seeking to remain competitive and meet the demands of today’s environmentally conscious consumers. By embracing sustainability, manufacturers can not only reduce their environmental impact but also drive innovation, improve efficiency, and create a more sustainable future for the industry. Sustainable manufacturing in the automotive parts industry is not just a trend – it is a necessary evolution towards a more sustainable and responsible future.